Prima Karya Dirgantara

AIRCRAFT GENERAL SUPPLY

RIVET CR

Bulbed CherryLOCK®rivets are locked spindle and flush fracturing structural rivets. They conform to Procurement Specification NAS1740 and Standards Pages NAS1738 and NAS1739.

The bulbed CherryLOCK®rivet is a complete shear fastening system. Its features can be utilized for optimum strength and performance in both thick and thin sheets.

It provides the highest possible design integrity, particularly in double dimple or high vibration areas.

All fasteners should be specified and used in accordance with manufacturer’s recommendations, using the grip range and hole size information provided in this catalog.

BULBED CHERRYLOCK®DESIGN FEATURES

• Large Bulbed Blind Head

Similar to a solid rivet

Ensures higher tensile, shear and fatigue strengths

• Steel and Inconel Stem

High stem break load provides high preload Higher fatigue strength

• High Sheet Clamp-Up

Increased fatigue strength

• Oversize Shank

Higher shear strength

Lower flush head height for use in thin sheets

• Predictable Hole Fill

Meets requirements of NAS1740

• Mechanical Locked Stem

Assured structural reliability in blind and non-blind applications

Exceeds fatigue requirements of NAS1740

• Genuine Flush Fracturing Spindle

No shaving, even in thin sheet applications

• Head Marking

Grip, materials and manufacturer’s identification for installed inspection

• Self-Inspecting (per NAS requirements)

STRENGTH

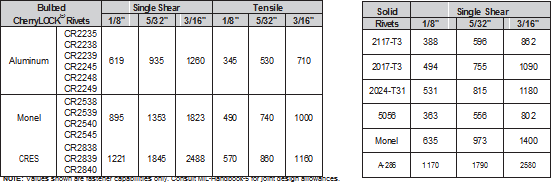

Minimum ultimate rivet shear and tensile strength (lbs.) per NAS 1740. Test method per NASM1312 -8 and -20.

INSTALLED WEIGHTS Pounds per 1000 pieces (Ref.)

D5 Creation

D5 Creation